Sinox Manufacture

High-quality and Safe Lock Solutions Customization

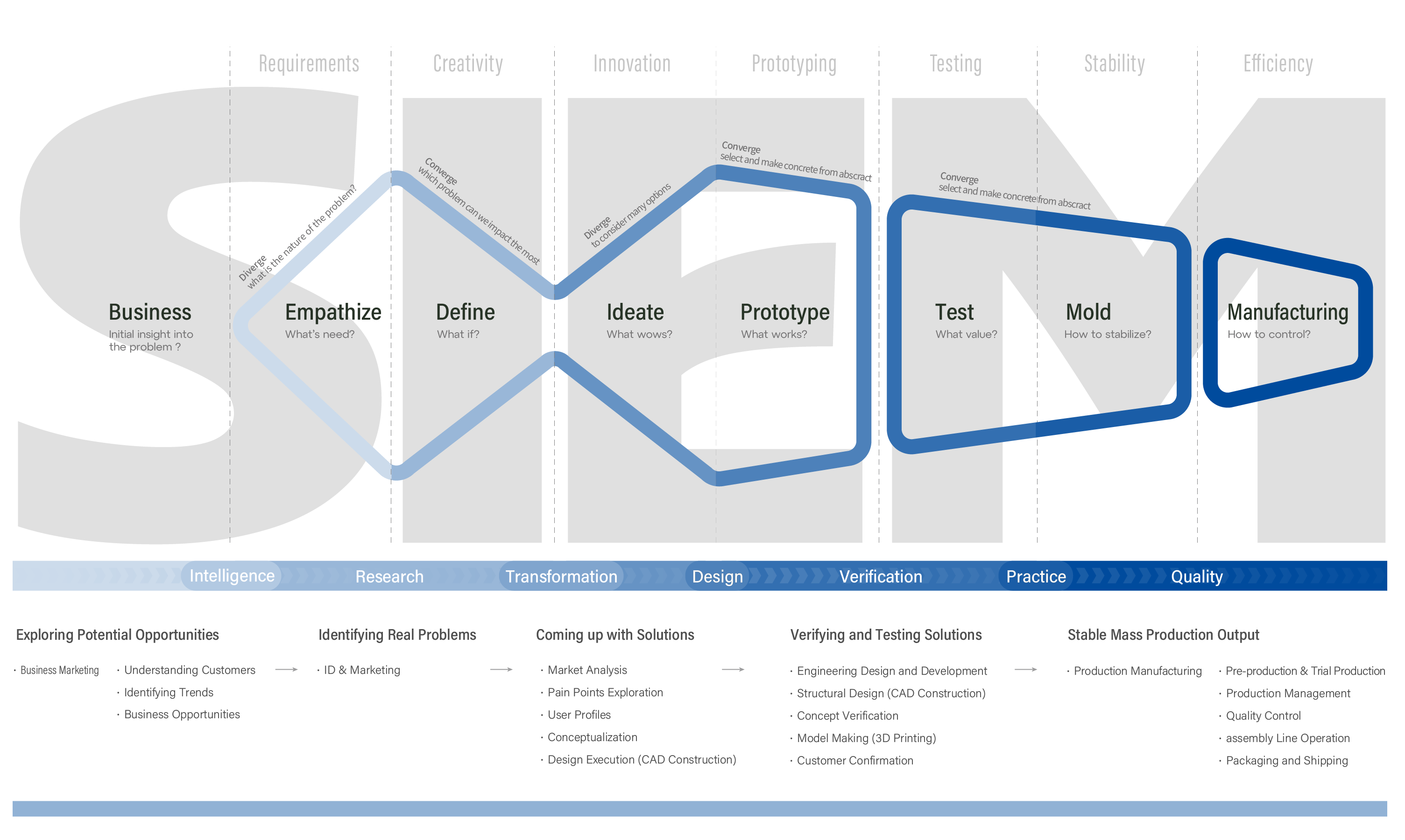

ODM/OEM/JDM Innovation and Development Oriented, Creating One-stop Development - Production - Manufacturing

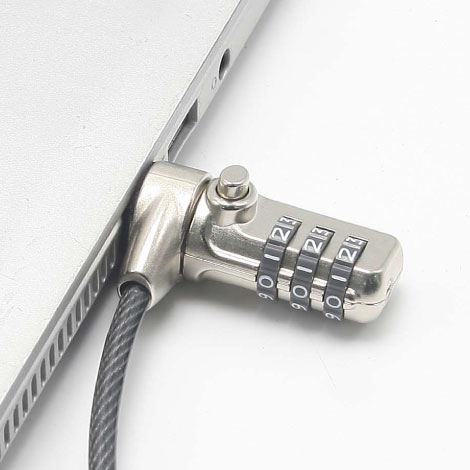

Since 1978, Sinox has possessed expertise and technology in locks, having developed locks widely applied to meet the needs of customers in seven major application categories.

With over 44 years of design and development experience, we understand that existing locks may not address all requirements. Sometimes modifications are necessary, or you may require an entirely new product. Our industrial designers and technical experts can provide relevant resources and propose corresponding solutions tailored to your needs or specific specifications. Our business and engineering teams will collaborate with you to develop the most suitable lock solutions for your security needs.

View more abour our products: Sports & Outdoors, Office NB & 3C, Two-wheel, Traveling & Luggage, Hardware, Cabinets, E-Lock

Inquire now: https://www.sinoxlock.com/contact/contact.html

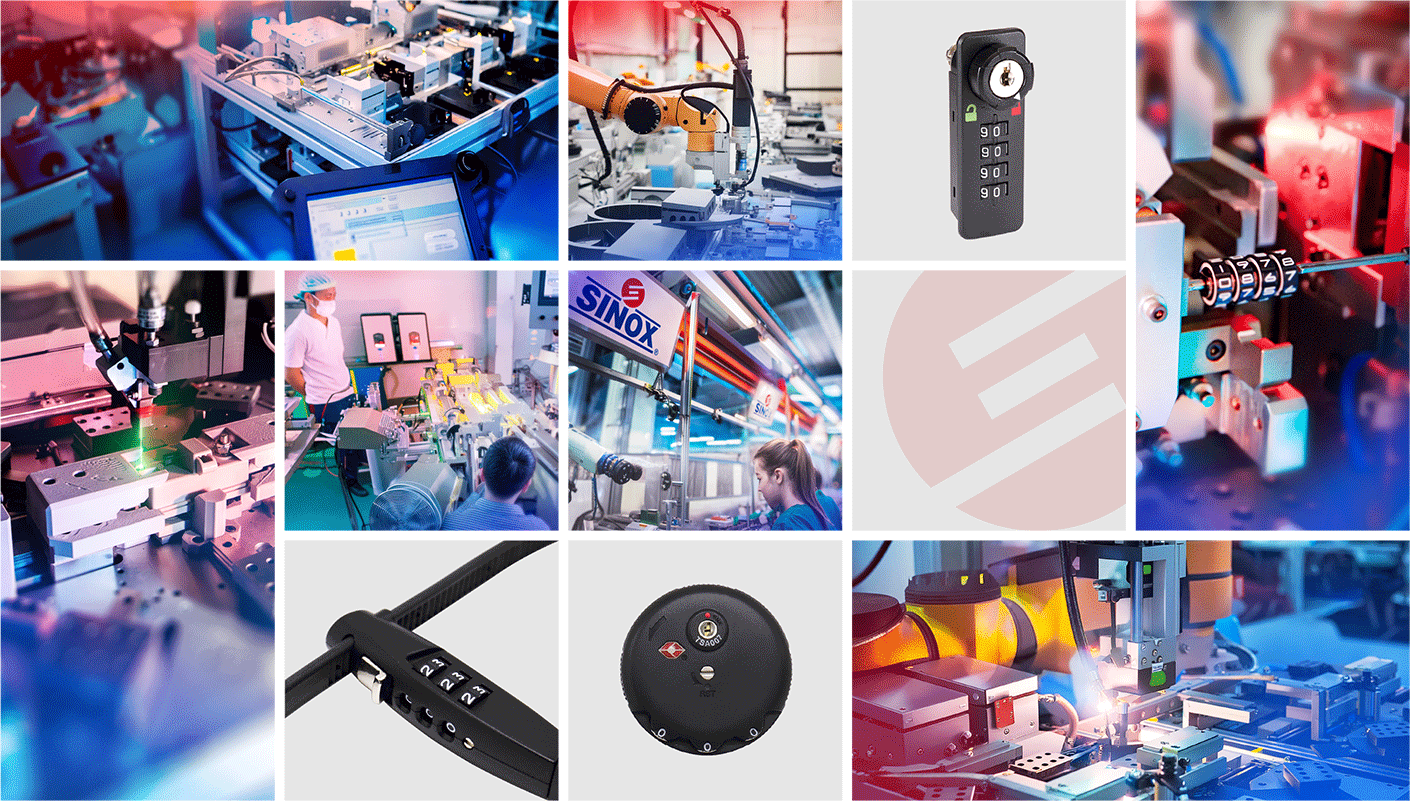

The Magician of Locks: SINOX Lock Mechanisms & Manufacturing Capabilities

SINOX's R&D team possesses extensive knowledge in die casting (zinc, aluminum), metal stamping, injection molding, electronic, and CNC machining of parts and mold design. Through these manufacturing processes, we are able to provide corresponding solutions through the correct handling methods.

Moreover, in the production and assembly of locks, we can adjust materials, assembly, and packaging services comprehensively according to the customized needs of corporate clients.

SINOX Manufacturing Highlights

- Manufacturing Highlights Smart Scheduling System: Pre-simulates order scheduling, accurately predicting delivery/capacity load.

- Kanban Management System: Improves operational efficiency using systems like ESOP.

- Human-Machine Collaboration Production: Leading traditional lock industry, enhancing production efficiency and quality stability.

- Semi-Automatic Number Lock Equipment: SINOX innovatively develops semi-automatic number lock assembly equipment independently.

- Automated Quality Control Monitoring Equipment: Features a quality monitoring system with quantifiable data.

SINOX Laboratory with over 19 Lock Quality Verifications

SINOX is ISO 9001:2015 certified, and we have been operating under ISO quality management guidelines. We prioritize product quality, assisting customers from concept to production, and have accumulated over 500 patents in multiple countries.

To verify the quality of our products, we conduct in-house verification, including internal tensile and drop load testing, salt spray testing, and customized durability and cycle testing. Additionally, we can conduct tests in external accredited laboratories to meet more complex requirements.

SINOX Laboratory Verification Items: Measurement-related

- 2.5D manual optical measurement

- Rockwell hardness measurement

SINOX Laboratory Verification Items: Strength-related

- Tensile testing

- Impact testing

- Freeze testing

- Torque resistance testing

- Destructive testing

SINOX Laboratory Verification Items: Reliability-related

- Cabinet lock knob/key lock testing

- Bicycle lock opening/closing lock testing

- Latch spring life testing

- Position sensing testing

- Salt spray testing

- UV testing machine

- Dustproof/waterproof testing

- Rubber eraser wear resistance testing

- Adhesion testing

- Pencil hardness testing

- Roller testing

- Drop test

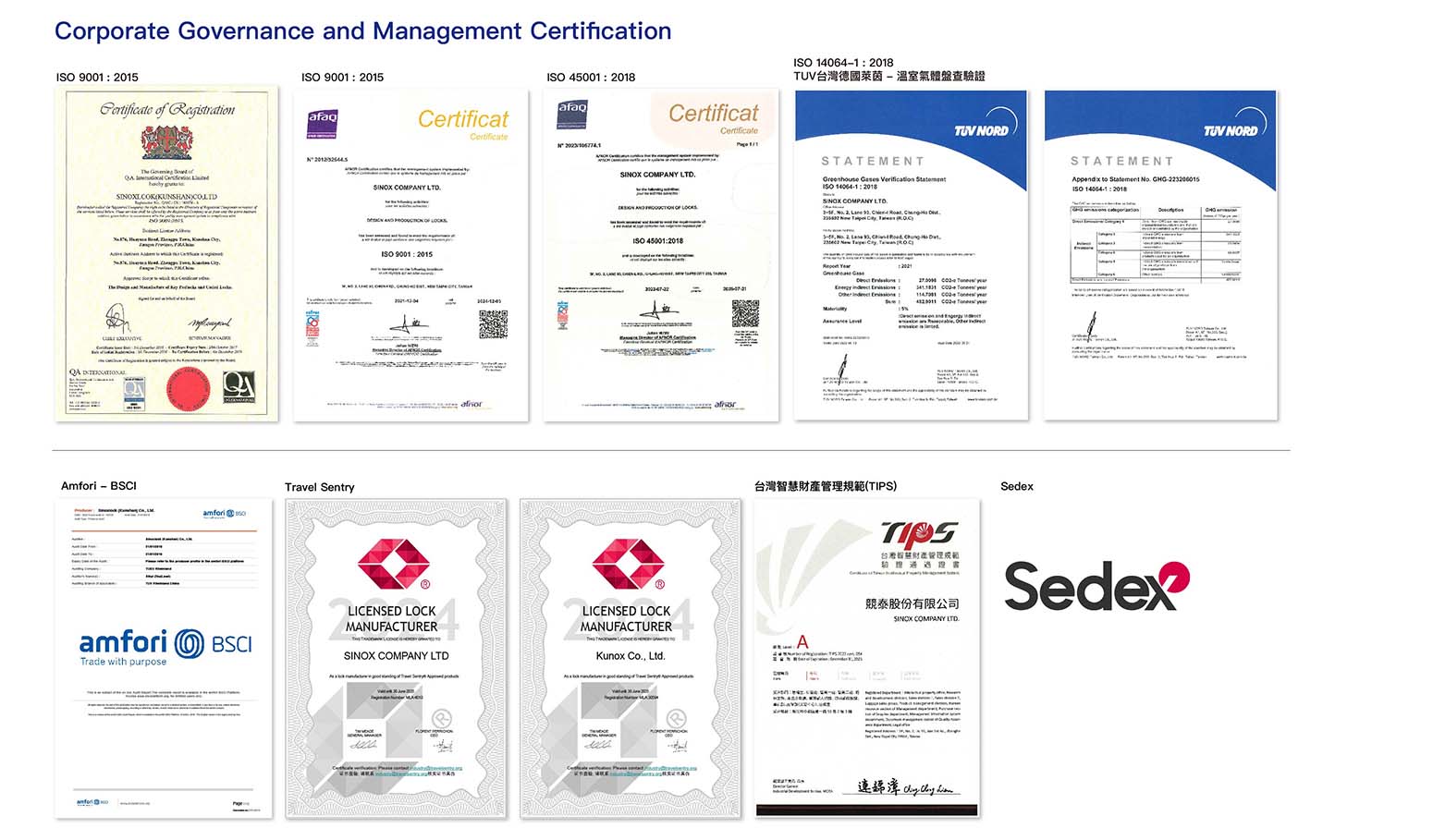

SINOX Awards and Global Certifications

Since 2006, SINOX has had the opportunity to collaborate with several world-renowned manufacturers to jointly develop and produce certified locks. Subsequently, the professional SIEM team formed project plans, led by business principals. SINOX's export products have passed certifications from multiple countries, demonstrating stable quality in design and production and establishing a solid presence in the certified lock market.

Over the years, SINOX has received various awards and certifications, including the Taiwan Top Ten Outstanding Enterprises Golden Award, Ministry of Economic Affairs SME Award, Outstanding Design Product Award from the Foreign Trade Association, Red Dot Design Award, COMPUTEX TAIPEI d&i awards 2010, Golden Pin Design Product Certificate, ART Certified, SSF Certified, SOLD SECURE Certified, TSA Recognized, and many other international certifications, earning international recognition for its design and safety research and development efforts.

ART Certificate: is to enhance the theft resistance level of two-wheelers (bicycles, light motorcycles, scooters, and motorcycles) through standards. SINOX's WD0125 / WL2001 / WL3001 / WL6002 products have obtained ART certification.

SOLD SECURE: is dedicated to evaluating the security of locking products through artificial attack testing, thereby reducing the likelihood of crime and risk. SINOX's WL2001 / WL3001 / WL3002 products have also obtained SOLD SECURE certification.。

SBSC: is to provide its customers with a strong competitive advantage that will promote their businesses both in a Swedish and in an international perspective through the certificates it grants.

Furthermore, in Europe, product quality and safety are ensured through specialized testing organizations. SINOX's product line has received ART certification. Additionally, in terms of OEM products, they have been certified by Classe SRA (FRA) and SSF (Sweden)..jpg)

Red Dot: The Red Dot Design Award is a competition focused on product design, conveying design excellence and concepts. SINOX'sWL0798 product has won the Red Dot Design Award.

Golden Pin: The Golden Pin Design Award aims to encourage designers to pursue excellence and innovation, promoting outstanding award-winning designs. SINOX'sPL0383/ PL0567 / RL0552 / RL0675 / WL0798products have won the Golden Pin Design Award.

ISO: is a universal standard established by the International Organization for Standardization to assist businesses in maintaining product and service quality, ensuring consistent and stable quality. SINOX has obtained ISO 9001 Quality Management System and ISO 45001 Occupational Health and Safety Management System certifications.

TUV: is the Taiwan German Rhein - Greenhouse Gas Inventory Verification, aimed at greenhouse gas verification. SINOX has been certified to assist businesses in achieving sustainable low-carbon development.

Amfori-BSCI: is a code of conduct for social responsibility initiatives aimed at monitoring and assessing workplace standards throughout the global supply chain to ensure that all suppliers treat workers humanely and legally. SINOX is certified to assist businesses in achieving sustainable trade.

In 2008, SINOX applied for certification from the Suppliers Ethical Data Exchange (SEDEX) based in London, UK, and passed the SEDEX Members Ethical Trade Audits (SMETA), demonstrating that SINOX's operations comply with labor standards and prioritize employee working conditions.

The Travel Sentry certification obtained by SINOX Travel Sentry is a result of the strict inspections carried out by the Transportation Security Administration (TSA) on checked baggage at over 400 airports in the United States after the 9/11 terrorist attacks in 2001. Today, all passenger luggage locks are required to use TSA-approved customs locks to prevent locks from being damaged during luggage inspections.

Successful Clients

The name of Innovation, Service, and Quality

Established in 1978 by a team of aerospace engineers, Sinox has since grown into a world renowned security lock manufacturer distinguished for its innovative design, and manufacturing of quality products. Over 40 years of experience supported by a team of 50 designers and engineers, our products have won much acclaim among our global clients. Here we introduce our 6 major product categories and clients in each category:

Should you require further assistance, please fill out the following form and we will contact you shortly. Thank you!

English

English 繁體中文

繁體中文 简体中文

简体中文