The Power of Recycled Aluminum: Eco-Friendly Locks Made from Recycled Aluminum.

"Do you know which products are made from recycled aluminum today?"

"Why are brands like BMW, LEXUS, and Porsche competing to use recycled aluminum?"

"What exactly is recycled aluminum? Apple products are already using recycled metals!"

As global environmental awareness continues to rise, both major brands and consumers not only pursue product functionality but also increasingly focus on the 'environmental impact' of their choices.

In addition to plastic and paper recycling, have you heard of "recycled aluminum"?

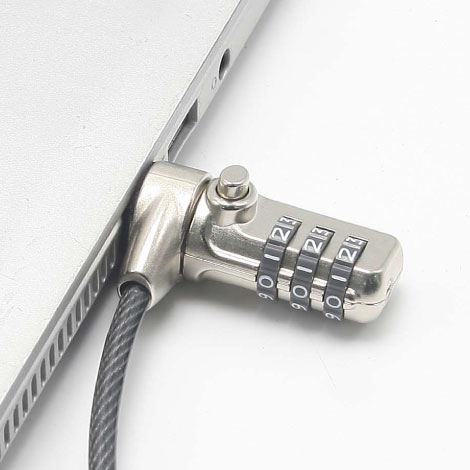

By using recycled aluminum to produce everyday items, locks, and building materials, we can not only effectively reduce the carbon footprint but also fully utilize the characteristics of aluminum, allowing locks to be durable, lightweight, and eco-friendly!

What is Recycled Aluminum?

Recycled aluminum refers to aluminum material that is reused after aluminum products are collected, cleaned, and reprocessed.

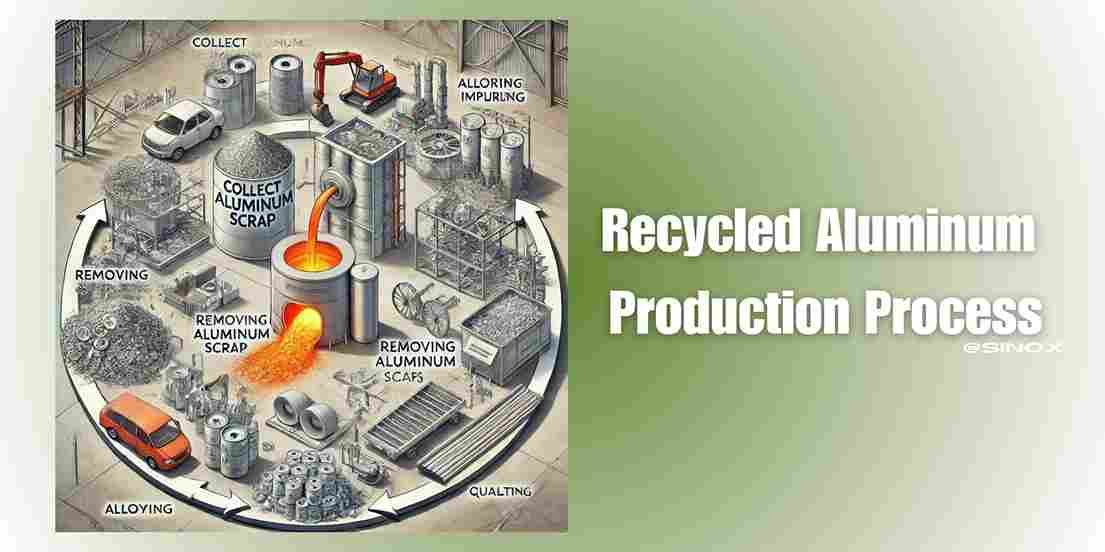

Production Process:

- Collecting Aluminum Waste

Materials are recovered from various aluminum products, such as car parts, construction materials, and aluminum cans. Ensuring diverse and sufficient sources of scrap aluminum provides a steady supply of recycled aluminum. - Sorting and Cleaning

Recycled aluminum waste is sorted based on different grades and alloy compositions. Physical or chemical methods are used to clean the aluminum, removing grease, dust, and other impurities to ensure the material's purity. - Melting

The aluminum scrap is heated in specialized furnaces, melting it into liquid aluminum. Furnace temperatures typically reach around 660°C to ensure the aluminum is fully liquefied. - Removing Impurities

During the melting process, filtering or refining techniques are used to remove non-aluminum impurities, such as iron and silicon, ensuring the final aluminum meets production quality and purity standards. - Adding Alloy Elements

Depending on the usage requirements, other metal elements (like copper or magnesium) are added to the liquid aluminum to enhance the mechanical properties and strength of the recycled aluminum. - Casting and Forming

The processed aluminum is poured into molds to form aluminum ingots or sheets. Recycled aluminum ingots can be used as base materials for further processing in various industries. - Extrusion and Processing

Aluminum ingots are further processed through extrusion, rolling, and other procedures to form products such as sheets, pipes, and aluminum bars. - Quality Inspection

Final recycled aluminum products undergo quality inspection to ensure they meet standards for mechanical performance, corrosion resistance, etc. The physical and chemical properties of the products are adjusted according to usage needs.

Compared to extracting aluminum directly from ores, the process of producing recycled aluminum can save approximately 95% of energy while also reducing greenhouse gas emissions!

The quality of recycled aluminum is no different from that of primary aluminum and retains the excellent thermal conductivity, corrosion resistance, and plasticity, making it an essential eco-friendly material choice for various manufacturing industries!

The Green Key: Recycled Aluminum

Protecting our one and only Earth is not just a personal responsibility—businesses must also actively participate in environmental efforts. At SINOX, we enhance innovation in lock design and development while also considering how to combine locks with eco-friendliness to reduce harm to the planet.

Our team is currently developing locks made with "80% recycled aluminum," which not only offer lightness, durability, and resilience but also reduce environmental impact by up to 68% during the manufacturing process. Recycled aluminum retains all the benefits of primary aluminum and provides a more sustainable solution for the modern lock market!

By promoting the application of recycled aluminum, the lock industry can continue to innovate while contributing to the global environmental cause. This is not only a trend in product upgrades but also a reflection of SINOX's commitment to ESG values, working together to protect the planet.

English

English 繁體中文

繁體中文 简体中文

简体中文