How is Plastic Recycled and Reborn?

We often crush plastic bottles and clean plastic packaging for recycling. But did you know? Taiwan's annual plastic demand is about 13.04 million tons, while the actual recycling rate is only 40%! This means that out of a large amount of plastic waste, only 9% is reused...

Although recycling is an important step in handling plastic waste, it cannot keep up with the speed of plastic production, use, and disposal. Facing the serious waste problem today, reducing the production at the source is essential, but we also need effective reuse and to enhance the economic value of plastic recycling to truly solve the problem. But do common plastics really have a chance for regeneration? Do you know of any cases of recycled plastic waste reuse?

The Benefits of Plastic Circular Recycling!

Whether it's regular plastic or PCR (Post-Consumer Recycled) plastic containers, products need to undergo compatibility and stability testing to ensure they are compatible with the chosen packaging containers and that quality is stable.

Advantages of PCR recycled plastic containers:

- Odor: PCR recycled plastic has no smell, just like regular plastic.

- Color: Compared to new plastic, PCR recycled plastic may appear slightly yellow or gray.

- Stability and Compatibility:

PCR recycled materials often have many black specks and impurities, with a gray or yellow hue, because post-consumer plastics come from various collection points, which usually gather all kinds of plastic bottles. Even the strictest processing and pelletizing cannot eliminate all particles.

The Five Steps of Plastic Waste Recycling

The diversity and practicality of plastic have made it an indispensable material in modern life. For instance, major sports brands like Nike and Lululemon design everyday clothing and products using recycled materials. As plastic recycling technology matures, more and more recycled plastic products are appearing in the market. From containers and fashion apparel to construction materials, plastic recycling is everywhere.

The four steps of plastic recycling:

- Plastic Classification: The first step in plastic recycling is classification, as different plastic materials have varying chemical and physical properties. Therefore, plastics are separated based on material types, such as PET (Thermoplastic), HDPE (High-Density Polyethylene), and PVC (Polyvinyl Chloride). This can be done through manual or automated sensing systems.

- Cleaning and Crushing: After classification, plastics are thoroughly cleaned to remove residual impurities, grease, and other attachments. The cleaned plastic is then crushed into small particles, which facilitates further processing and reduces the energy needed to produce new products.

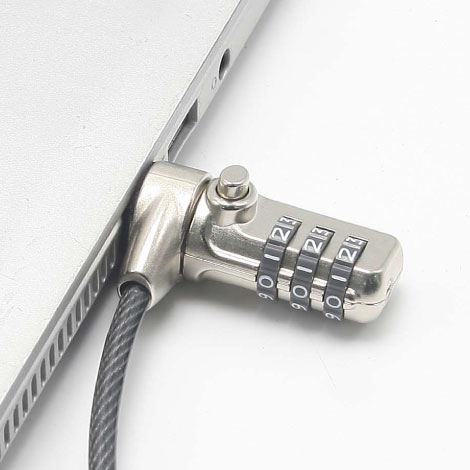

- Heat Melting and Reshaping: The plastic particles are heated to high temperatures until they melt into a liquid state, removing even more impurities and granting the plastic new plasticity. This liquid plastic can then be reshaped into various products, such as bottles, containers, or even security locks.

- Quality Testing and Recycled Applications: The reshaped plastic products undergo strict quality testing to ensure they meet performance standards. These recycled plastic materials can be used in various fields, including construction materials, household items, and even eco-friendly locks, providing practical solutions for a circular economy.

.jpg)

SINOX's eco-friendly locks are made from recycled plastics, extending the lifespan of plastic while reducing resource waste and carbon emissions. These recycled materials will play a greater role in various fields. In the future, eco-friendly materials will bring more innovation to lock design, contributing to the sustainable development of our planet!

SINOX Breaks Technical Limitations, Supporting the Start of Circularity

SINOX pursues eco-friendly principles from product packaging to production and recycling, providing high-quality locks while designing and innovating for customers. With products like tablet locks, cabinet combination locks, mailbox combination locks, TSA customs locks, and outdoor locks, SINOX uses 85% recycled materials in the design stage to ensure that every part of the product can be recycled and remade at the end of its life cycle.

SINOX's recycling program encourages partners and consumers to participate, with collected products being crushed and remade. By improving designs, we strive to reduce the use of new plastics, create a complete recycling mechanism, and achieve zero waste goals, allowing every piece of plastic waste to be reborn through regeneration!

Interested in seeing how SINOX integrates recycled materials into our products? Visit our Green Locks page to explore our eco-friendly solutions and join us in making a sustainable impact.

English

English 繁體中文

繁體中文 简体中文

简体中文.jpg)